NB7CJ

Heavy duty machine body and most mechanical machine parts are proceed by advanced CNC machines for higher stability and longer service life without deforming ;

NCB612

Easy production management due to self-recording function. Automatic detection of panel size reducing man made mistakes. Adjustment of panel position by best compensation automatically to suit furniture assembly process. Open port for international popular software, compatible with many file formats like xml, mpr etc.

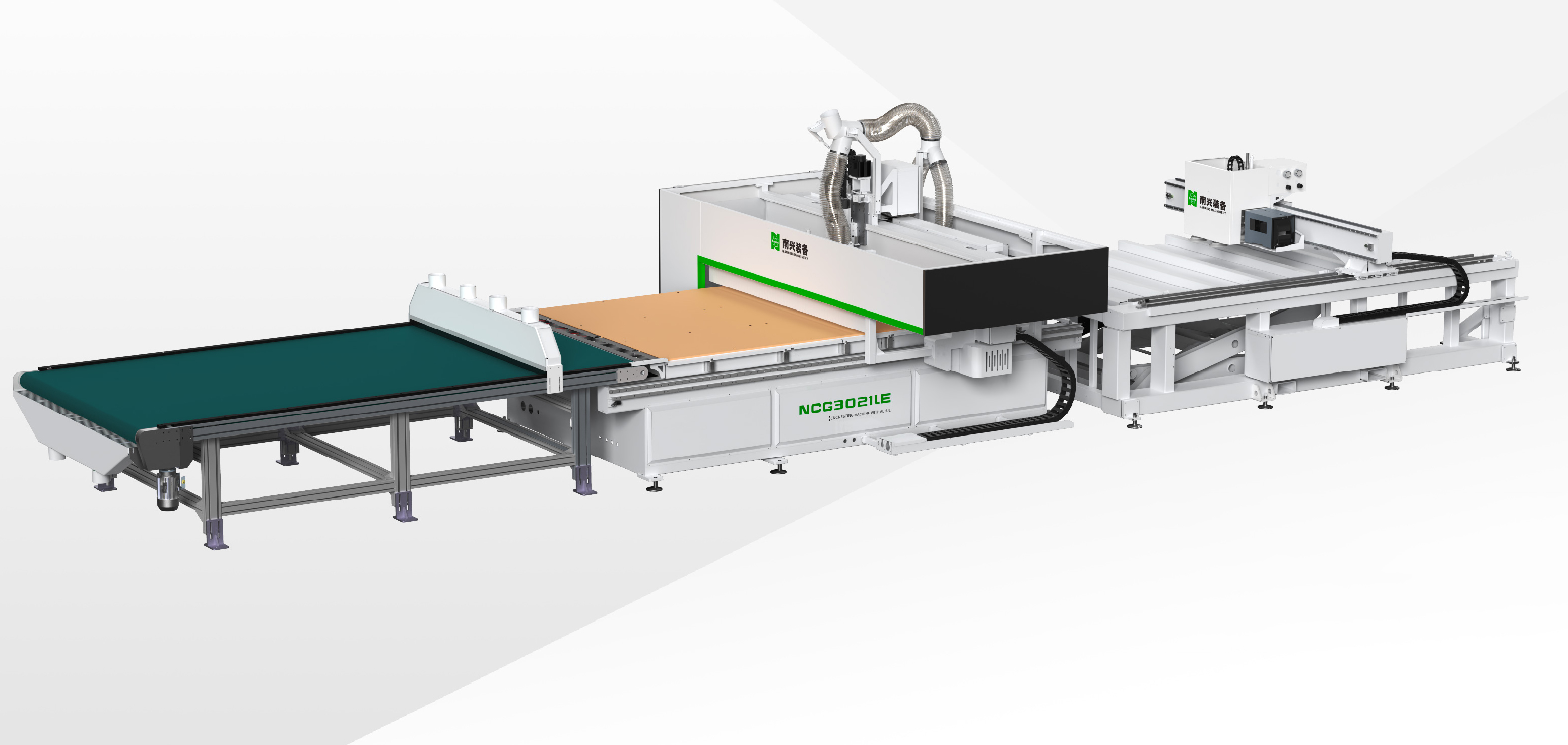

NCG3021LE

is a complete big table CNC line with automatic labeling and unloading, Top drilling, grooving, shaping, cutting could be done in one process. Specially twin gantries, each gantry has one 12kw ATC Italian main spindle and one 21-drills drilling block, double working efficiency, 2 gantries work synchronously thanks for optimizing algorithm of standard optimizing software. High cost-efficiency with great performance.

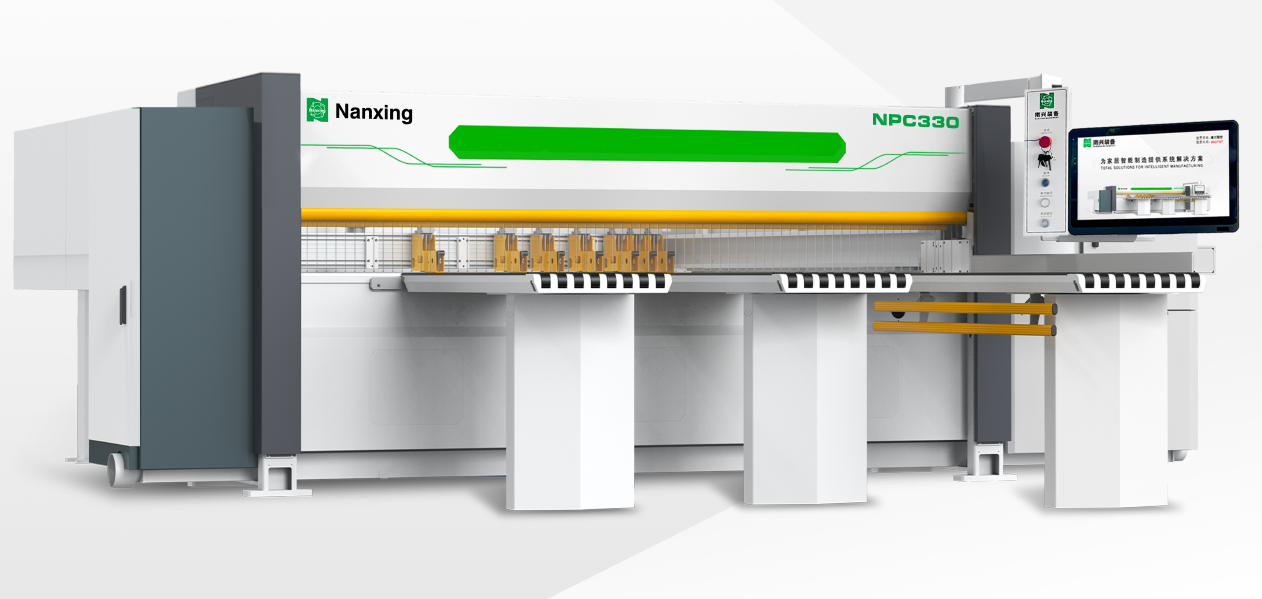

NPC330

Pressure beam automatically self-adjusted according to the total height of panels, to shorten the travel range, hence higher efficiency.

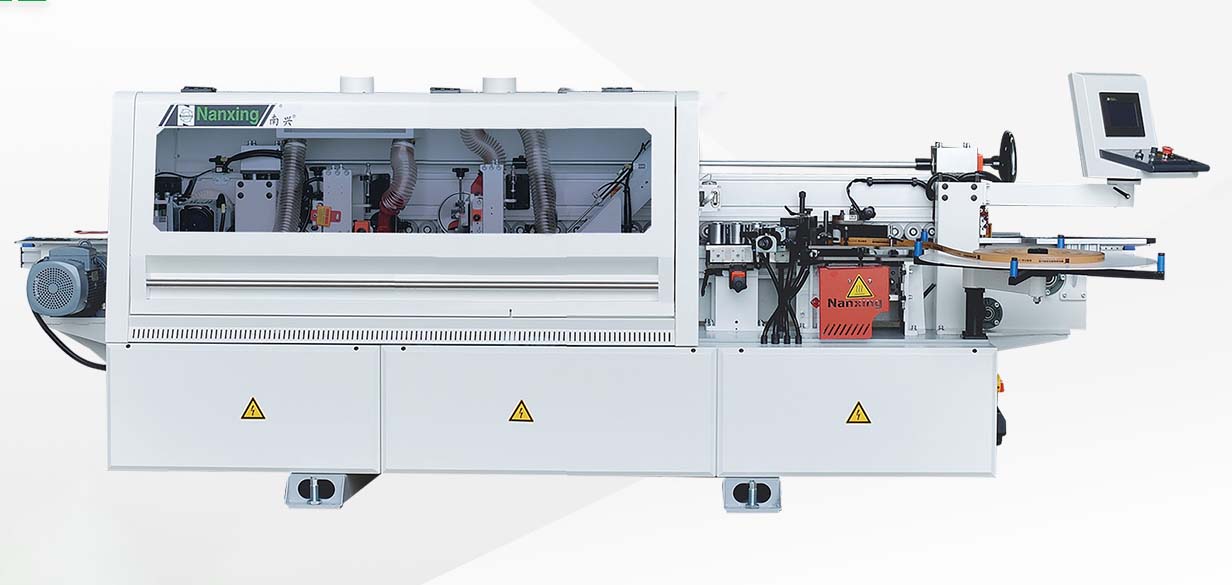

NBC332S

Gluing, snipping, end trimming, fine trimming, scrapping, buffing work of edge banding could be done automatically in one process.